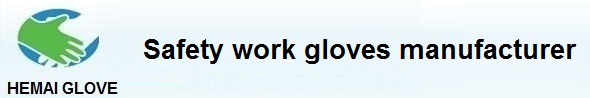

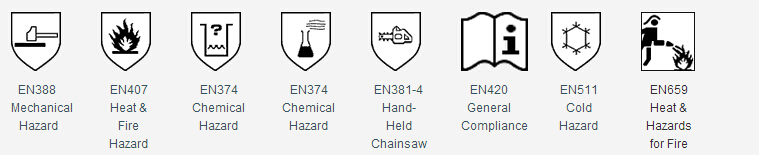

EN388 Mechanical Hazard

This diagram details the testing categories for BS EN388: 2003. A tested item is given a performance rating of 1 to 4 (lowest to highest) on some or all of the listed categories. The 'blade cut resistance' test is an exception as it measures from 1 to 5. Frequently an 'x' will replace one or more of the numbers, this means that the corresponding test was not performed.

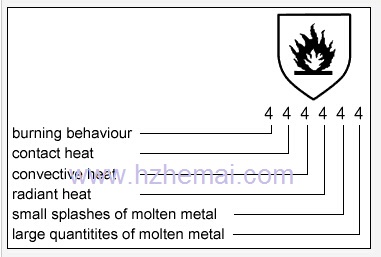

BS EN407: 2004

Protective gloves against thermal risks (heat and/or fire)

This diagram details the testing categories for BS EN407: 2004. A tested item is given a performance rating of 1 to 4 (lowest to highest) on some or all of the listed categories. Frequently an 'x' will replace one or more of the numbers, this means that the corresponding test was not performed.

Contact Heat Times

The following table details the performance levels for the 'contact heat' category:

|

Performance level

|

Contact temperature (degrees C)

|

Threshold time (seconds)

|

|

1

|

100

|

>15

|

|

2

|

250

|

>15

|

|

3

|

350

|

>15

|

|

4

|

500

|

>15

|

Protective gloves against chemicals and micro-organisms

BS EN374

This pictogram is displayed on gloves that are waterproof and give low chemical protection.

Protective gloves against chemicals and micro-organisms

BS EN374

This pictogram is displayed on gloves that comply to penetration and permeation requirements. Gloves that carry this symbol have been successfully tested against at least 3 different chemicals. The pictogram is accompanied by the relevant code letter(s) of these chemicals according to the following chart:

|

Code letter

|

Class

|

|

A

|

Primary alcohol

|

|

B

|

Ketone

|

|

C

|

Nitrile compound

|

|

D

|

Chlorinated paraffin

|

|

E

|

Sulphur containing organic compound

|

|

F

|

Aromatic hydrocarbon

|

|

G

|

Amine

|

|

H

|

Heterocyclic and ether compound

|

|

I

|

Ester

|

|

J

|

Saturated hydrocarbon

|

|

K

|

Inorganic base

|

|

L

|

Inorganic mineral acid

|

BS EN420:2003

Protective gloves - general requirements and test methods.

This standard defines the general requirements and relevant test procedures for all protective gloves and is concerned with the following areas:

§ glove design and construction,

§ resistance of gloves materials to water penetration,

§ innocuousness,

§ comfort and efficiency,

§ marking and information supplied by the manufacturer.

Please note that the standard does not address the protective qualities of the gloves and so is designed to be used in conjunction with the appropriate specific European Standard.

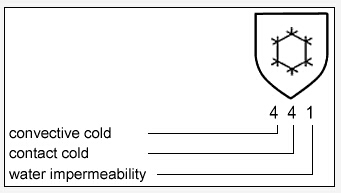

BS EN511: 1994

This diagram details the testing categories for BS EN511: 1994. A tested item is given a performance rating of 1 to 4 (lowest to highest) on some or all of the listed categories. Water Impermeability is an exception in this case, as this test is pass/fail - '1' signifies a pass. Frequently an 'x' will replace one or more of the numbers, this means that the corresponding test was not performed.

S EN659: 2003 Protective gloves for firefighters

This pictogram is displayed on gloves that comply to the 'European Standard for firefighters gloves.' For gloves to be compliant with this standard, they must be at the minimum:

§ Level 3 abrasion resistance (EN388)

§ Level 2 cut resistance (EN388)

§ Level 3 tear resistance (EN388)

§ Level 3 puncture resistance (EN388)

§ Level 4 burning behaviour (EN407)

§ Level 3 convective heat resistance (EN407)

Tests are also performed to guarantee a minimum standard for each of the following categories:

§ Radiant heat resistance

§ Contact heat resistance

§ Heat resistance of the lining material

§ Heat shrinkage

§ Dexterity

§ Seam Breaking strength

§ Time for the removal of the gloves

§ Resistance to liquid chemical penetration